Processing results

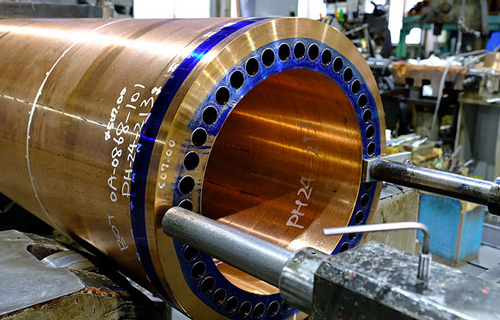

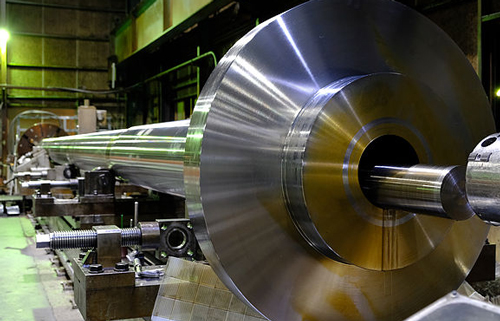

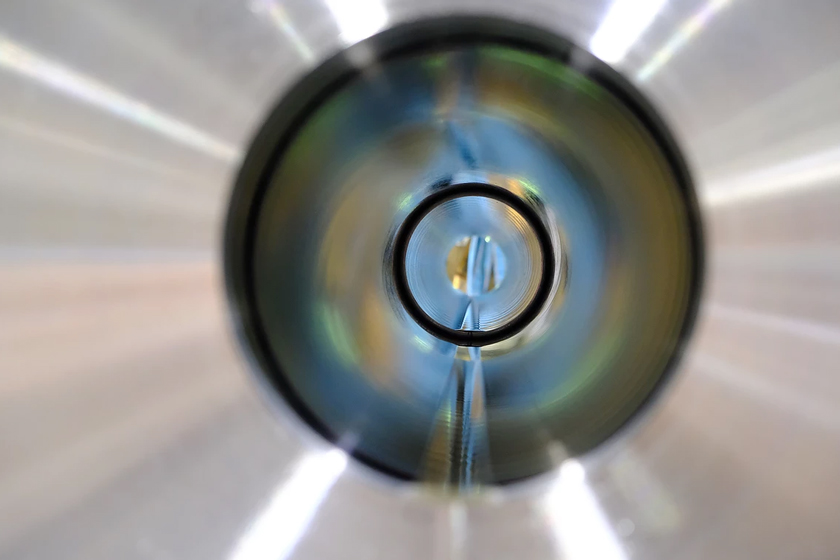

The parts drilled at our company are rolling rolls of steel mills for steel-related products, cylinders of injection molding machines and extruders for industrial machinery, center holes for screws, aircraft engines and parts, ship propeller shafts and precision machinery. Used for journal bearings, etc.

In this way, the BTA deep hole drilling technology is used throughout all industries.

| Aerospace industry | Aircraft leg parts, jet engines, special alloy seamless pipes (Hastelloy, Inconel, Nickel) |

| Automotive industry | Hydraulic cylinder, piston, camshaft |

| Railway industry | Vehicle axis |

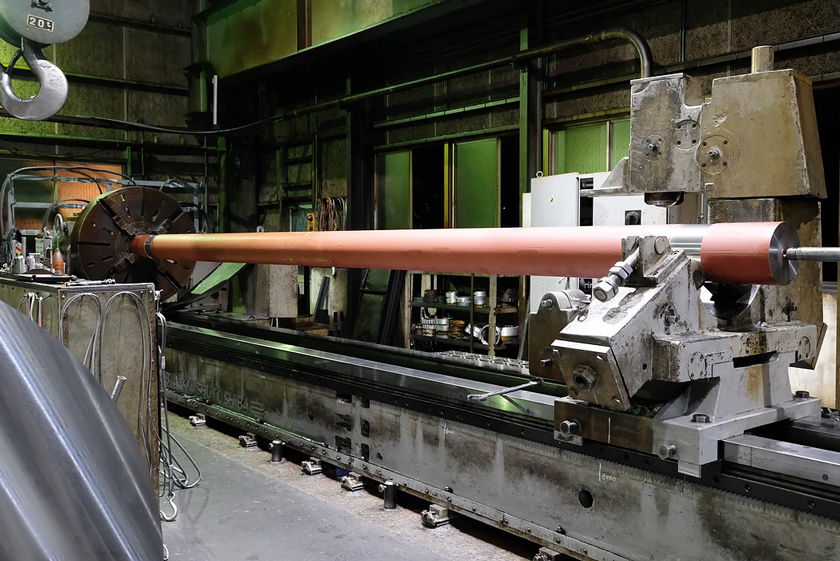

| Shipbuilding industry | Propeller shaft, intermediate shaft, engine parts |

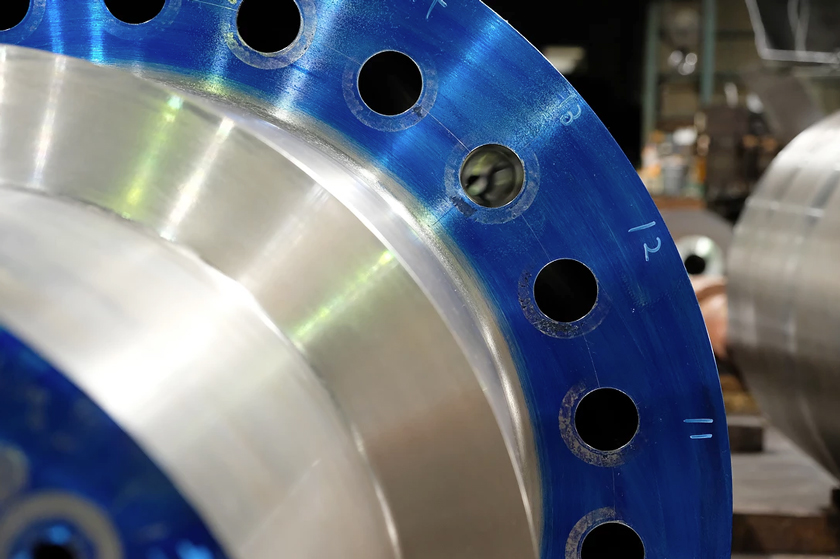

| Steel related | Roll sleeve, pinch roll, calendar roll, mold, coupling, mandrel shaft |

| Industrial machinery | Hollow shaft, drum shaft, spindle, cylinder for injection molding machine, shield machine parts |

| Power generation related equipment | Reactor inner pipe, core special pipe, turbine loader, water axle |

| Oil well gas industry | Stainless steel seamless pipe, oil holes |

| Defense industry | Cannon barrel |

| others | Ball screw |

Materials range from general steel to difficult-to-cut materials such as aluminum, titanium, Inconel, and copper.

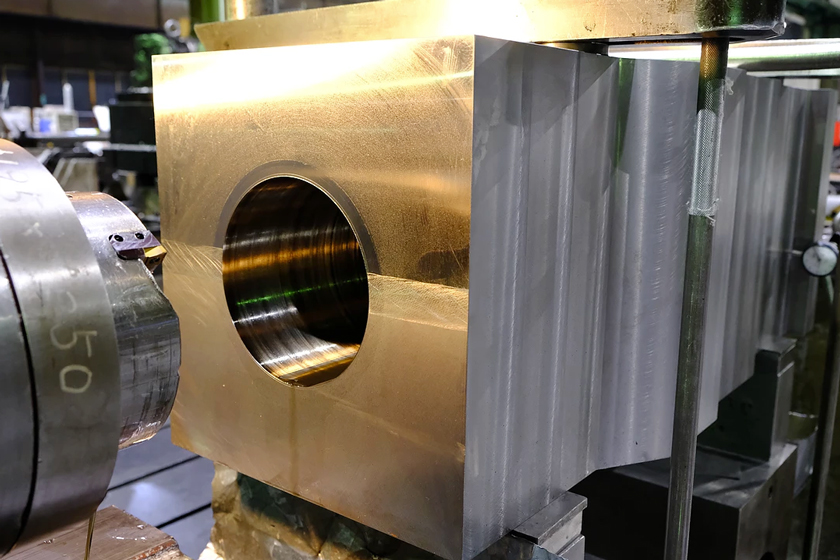

As for the shape, he can process various shapes such as round bars, square lumbers, and irregularly shaped lumbers.

≪ Work fixing / stationary processing example ≫

| ● Square lumber | SUS420 | 190L×430L×5,600L | Drill a large number of holes with hole diameters of φ18 and φ20 and a depth of 5,600L. |

| ● roll | SCM440 | φ370×φ950×7,500L | Drill a large number of holes with hole diameters of φ25 and φ65 and a depth of 5,900L. |

| ● Manifold block | SS400 | 700L×800L×1,500L | Drill 65 intermittent holes with hole diameters from φ14 to φ145 |

| ● Drill 65 intermittent holes with hole diameters from φ14 to φ145 | Chilled | φ465×φ815×6,450L | Penetrate through 30 holes of φ30 |

≪ Work rotation processing example ≫

| ● Propeller axis | SF60 | φ930/φ315×19,900L | Hole φ125 penetration |

| ● pipe | SM440A | φ780×7,000L | Hole φ700 penetration |

| ● Difficult-to-cut material | Titanium | φ160×2,850L | Hole φ125 penetration |

| ● Difficult-to-cut material | Inconel 718 | φ110×2,500L | Hole φ65 x 2,300 Stop |

| ● Nuclear parts | SUS316L | φ250×4,800L | Hole φ95 / φ125 with steps |

| ● Aircraft parts | SCM材 | φ180×2,200L | Hole φ50 ~ φ120 8 stepped hole |

| ● Machine related | SCM440 | φ100×8,900L | Hole φ30 penetration, 300 times the hole diameter |

| ● Hydraulic cylinder | STKM13A | φ300×6,000L | Hole φ270 penetration, wall thickness 15t |

| ● Rolling roll | R80A | φ680×φ985×7,700L | Weight 35 tons, hole φ135 penetration, φ60 residual core |

| ● Billet | copper | φ280×1,100L | Drilling φ175 |

In addition, we undertake various BTA deep drilling processes. Please contact us.