What is ”BTA”?

This is a question that is always asked when we say the company name.

BTA is an acronym for "Boring & amp; Trepanning Association". The BTA method is one of the cutting methods for drilling deep holes in metal, and due to its structure, it is extremely excellent in terms of chip discharge, rigidity, and productivity. Therefore, it has the features that high-precision deep hole drilling can be performed at high speed and the finished surface is very good.

Pioneer of deep hole drilling

We, Nippon BTA, purchased the copyright of metal BTA type deep hole drilling tools from German machine tool and tool makers in 1952, and were established in 1959 for the purpose of selling deep hole drilling machines and tools.

First, the Kamata Factory, Kakogawa Factory, and Sagami Factory were newly established, and BTA method deep drilling processing was started. After that, the Kazo Factory was newly established, and the production of BTA deep hole drilling machines and deep hole drilling tools was started.

In this way, we have always been a pioneer in BTA deep drilling.

We are grateful to all of you for celebrating our 60th anniversary.

Do you have any problems like this, the person in charge of design and production technology?

● Can it be processed to this tolerance?

● Can it be processed in terms of material?

● What about the surface roughness?

● Is this the size of the material?

● Is it possible to process with this hole diameter and depth?

● Is it possible to do R processing in the back of the hole?

《 What is BTA method deep hole drilling? 》

Deep hole drilling (deep hole drilling) is one of the metal cutting processes.

Deep hole drilling is the process of drilling holes with a hole depth of 150 to 200 times the diameter, and there are BTA method and ejector method.

& nbsp;

BTA is an acronym for Boring & amp; Trepanning Association, and because the BTA method is structurally superior to the ejector method in terms of chip emission, rigidity, and productivity. It has the feature of being able to perform deep hole drilling at high speed and cleanly. That is why the BTA method is the first choice for deep drilling.

& nbsp;

In the ejector method, most of the cutting oil is sent to the head through the gap between the boring bar and the inner tube, and reaches the cutting edge part from the outer circumference of the head through the small hole of the head, and the chips are sent to the inner tube. Pour through the inside of the outlet to the outlet. Some cutting oil is ejected to the outlet through the slit in the inner tube.

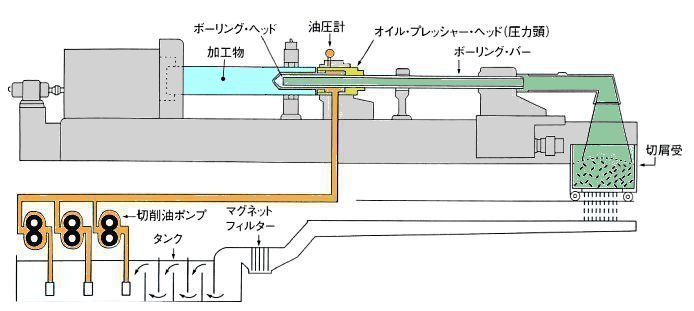

In the BTA method, on the other hand, the cutting oil is first sent from the tank to the pressure head in contact with the workpiece, then reaches the cutting edge through the ring-shaped space between the drilled hole and the boring bar, along with the chips. Return to the oil tank through the bowling bar. Therefore, since the chips do not come into contact with the inner surface of the drilled hole, it does not damage the inner surface of the drilled hole and can be drilled very cleanly. Since the boring bar is cylindrical, it is extremely resistant to twisting and bending and is extremely efficient. The drillable length can reach more than 100 times the hole diameter.

《 Types of BTA processing 》

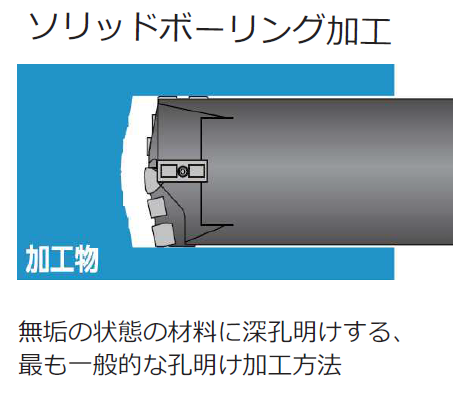

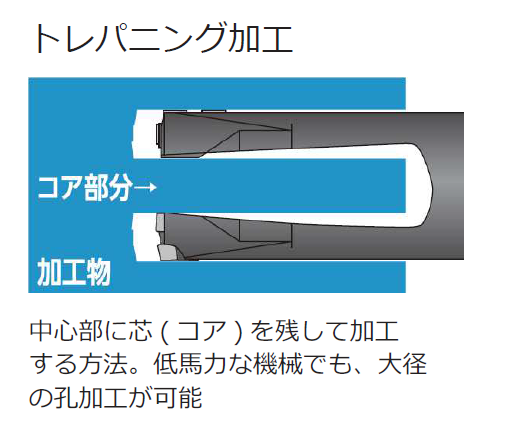

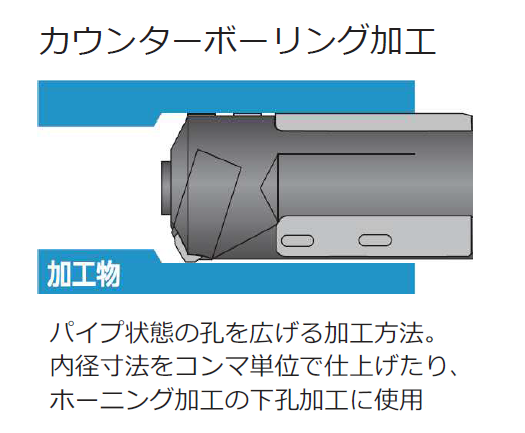

In BTA processing, there are three processing methods: solid boring processing, trepanning processing, and counter boring processing.